Cylinder Covers

DMI Dubai is a leader in the development of cost effective reconditioning methods for both conventional designs and latest generation of bore cooled cylinder covers in co-operation with OEMs and ship owners.

DMI Dubai's detailed inspection and 'Total Reconditioning System' are designed to bring components back to original dimensions and tolerances to provide a long and trouble free life. DMI Dubai uses the 'Calotte' method to recondition traditional B&W and Sulzer cast steel cylinder covers.

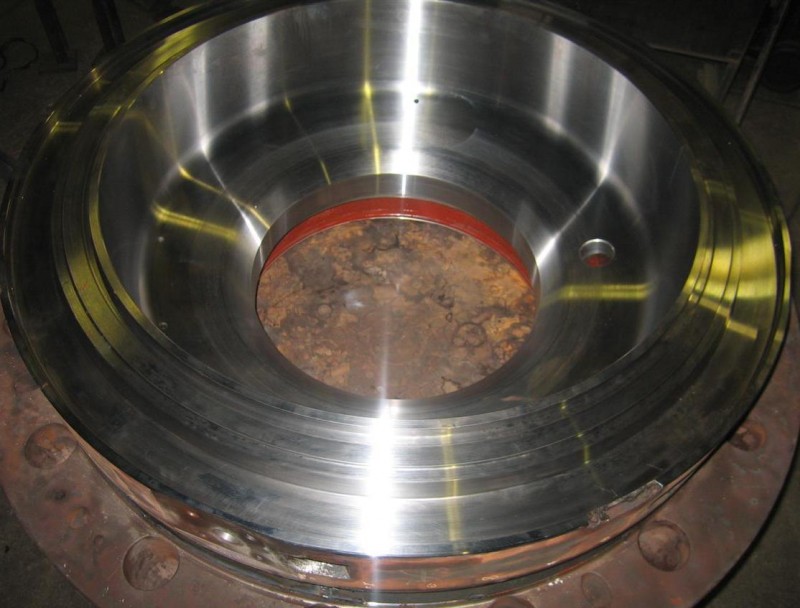

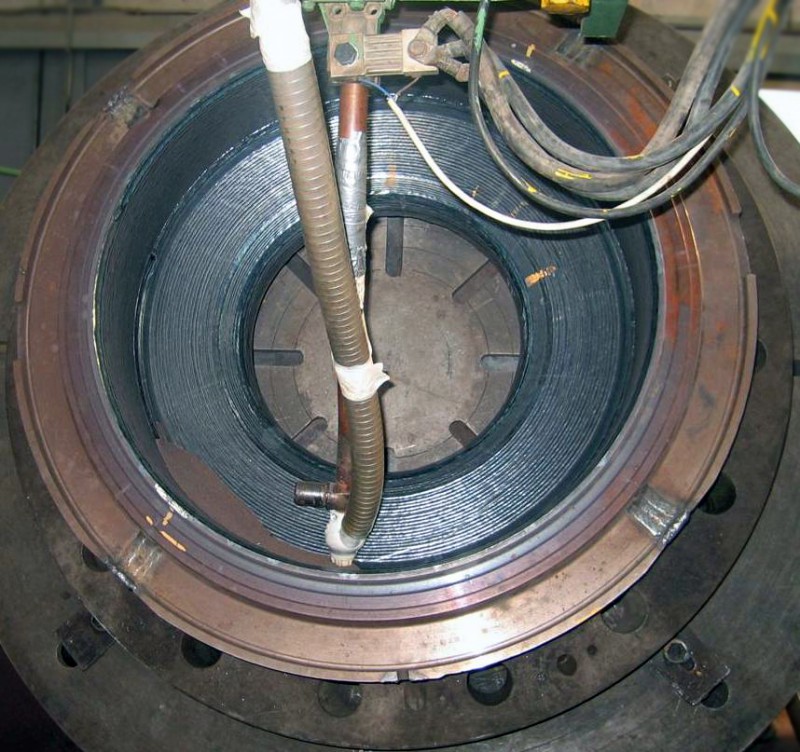

Bore Cooled Cylinder Cover

Modern bore cooled cylinder covers are manufactured from forged steel with cooling bores. Common engine types include MAN B&W, Sulzer & Mitsubishi. Failures during operation can be caused due to various problems, such as:

- Erosion and corrosion of air starting and safely valves

- Erosion and cracking in the area adjacent to fuel injector valves

- Cracking from the cooling bores due to chock-up of cooling water inside the bore

- Fretting of sealing faces and O-ring grooves.

Modern bore cooled MAN B&W, Sulzer and Mitsubishi covers can be reconditioned in a quick and cost effective manner to improve long term reliability of covers. DMI Dubai’s process involves following steps:

- A detailed inspection of the cylinder cover, removal of cooling water shield (if required).

- Removal of the combustion face and cooling water bores. The remaining material is further inspected to ensure that it is free of cracks.

- Welding of the combustion face, O-ring grooves and landing faces.

- Stress relieving under precise controlled conditions.

- Machining to specified dimensions.

- Re-drill the cooling water bores (if required).

- Machine spots adjacent to the fuel valve pockets are welded with a special nickel alloy (hard facing).

- Final machining.

- Final inspection including a hydraulic test and certification.

-

Cylinder Cover

-

Cylinder Covers

-

Cylinder Cover

-

Cylinder Cover

-

Cylinder Cover